A sanitary napkin embodies over a century of material innovation and health care. As an essential daily product for women, its safety has always been a major concern. From doubts about "black-hearted cotton" to rumors about fluorescent agents, various questions influence consumers' choices. So, how have sanitary napkins evolved to this day? How does the industry respond to common safety concerns?

I. A Brief History of Evolution

The prototype of the modern sanitary napkin emerged during World War I, when American nurses serving in France used bandages wrapped with medical cotton to create disposable menstrual products. After the war, highly absorbent fiber cotton used in battlefield medical care was applied to civilian use. In 1921, the first commercial disposable sanitary napkin was introduced.

Subsequently, key technologies continued to advance: in 1929, the tampon with an applicator was launched, and in 1969, the self-adhesive backing technology made sanitary napkins more convenient to use.

China's sanitary napkin industry began in the 1980s. In 1991, winged sanitary napkins were introduced to China, improving leak-proof performance; the following year, panty liners entered the market, enriching the product range.

Today, sanitary napkins are available in various categories: by surface layer—dry mesh, soft cotton, and pure cotton sanitary pads; by absorbent core—traditional fluff pulp composite, composite core, and new liquid sanitary napkins using porous absorbent polymers; and by type—regular size, winged sanitary pads, and pants-style.

II. Core Structure

A sanitary napkin is actually a composite of multiple layers of materials, mainly including: non-woven fabric, fluff pulp, super absorbent polymer, polyethylene film, hot-melt adhesive, and elastic materials. Fluff pulp and super absorbent polymer work together to absorb and lock in fluids.

Standard products typically have a four-layer structure: a skin-friendly top layer for quick penetration; a distribution layer to spread the fluid evenly; an absorbent core to store moisture; and a leak-proof bottom layer to prevent seepage. Designs like 3D side barriers and sealed edges further enhance protection reliability. Pants-style sanitary napkins add elastic waistbands and leg cuffs for more comprehensive protection.

III. Addressing Common Misconceptions

In response to common safety concerns, the industry provides the following explanations based on scientific standards:

-

Virgin Fluff Pulp vs. "Black-Hearted Cotton": The fluff pulp used in sanitary napkins is made from natural wood pulp, sourced from trees such as pine and spruce. It undergoes high-temperature cooking and purification processes, complying with national standards. "Black-hearted cotton" refers to prohibited recycled inferior fibers, which reputable manufacturers would never use this..

-

Impact of pH Value: The vaginal environment has its own strong regulatory capacity. As an external product, sanitary napkins do not alter the normal weakly acidic state of the vagina.

-

Fluorescence Phenomenon: Some raw materials contain natural fluorescent substances, which may appear under ultraviolet light. This does not mean prohibited migratory fluorescent whitening agents have been added. Judging safety based solely on fluorescence is unscientific.

-

Formaldehyde and Trace Impurities: National standards impose strict limits on formaldehyde content. Qualified products pose minimal risk. Trace impurities exist in extremely small amounts and do not affect safety when within permissible limits.

-

Production Environment and Live Insects: Modern production employs automated, enclosed assembly lines with high-temperature processing and visual inspection systems, along with strict pest control measures. The likelihood of live insects in finished products is extremely low. Cases reported by consumers are often related to improper storage, transportation, or home storage conditions.

IV. How to Choose

To make a scientific choice among numerous products, keep the following points in mind:

-

Check the Packaging: Legitimate products should clearly display information such as the product name, manufacturer, ingredients, hygiene license number and expiration date. Avoid products without proper labeling.

-

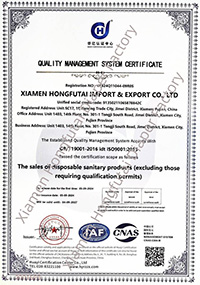

Consider Corporate Credentials: Prioritize brands with complete certifications, advanced production lines, and strict quality control systems.

-

Usage and Storage: It is recommended to change sanitary napkins every 2–3 hours to prevent bacterial growth. Store products in a dry, clean place and use them as soon as possible after opening to avoid moisture and mold.

After decades of development, China's sanitary napkin industry has achieved international standards in technology and craftsmanship. The industry will continue to innovate and enhance quality control to provide women with safe, comfortable, and reliable menstrual care solutions.